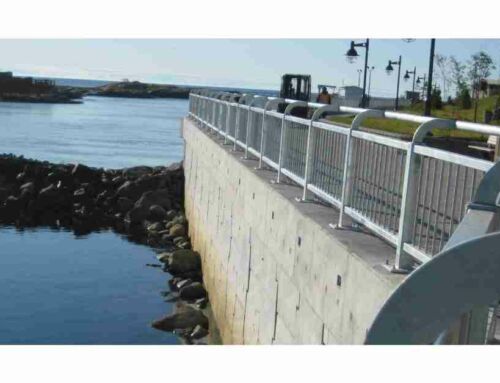

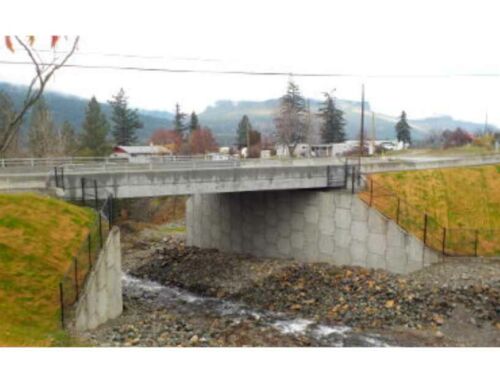

At the heart of Hopewell Development’s new community, Mahogany Lake is the largest community lake in Calgary. In order to create the 63 acre oasis, the developer recognized a need to build retaining walls in areas not only to allow traffic access to the two exclusive islands, but also to maximize the lake area while also allowing development close to the water’s edge. Reinforced Earth was chosen to design and supply the nearly 3 km of submerged walls supporting sidewalks, road traffic and backyards.

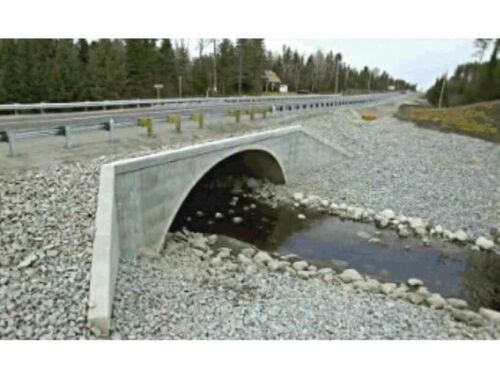

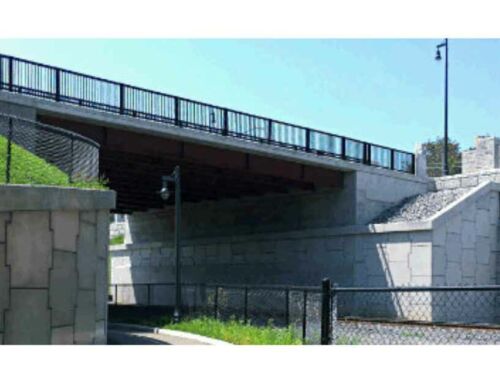

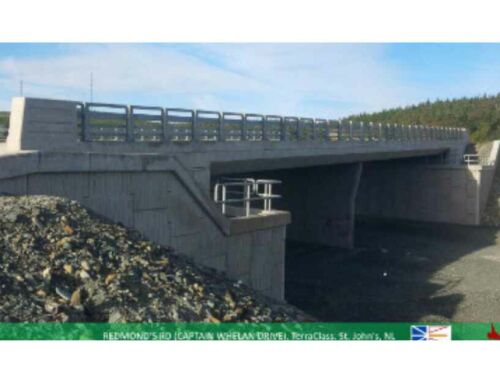

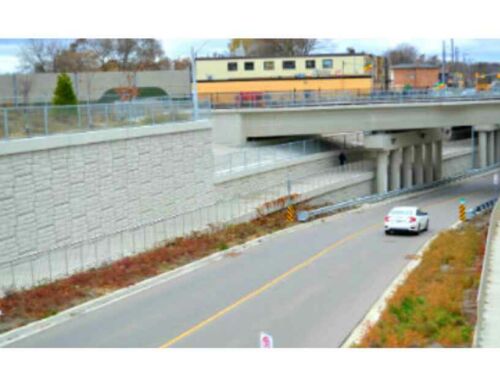

Several key features include 2 bridge walls that include smaller planting walls allowing the growth of vegetation. Also included are two walls that contain stairways allowing pedestrian traffic from the top down to the water’s edge. The construction of the North bridge wall started in the spring of 2013 with final construction of the South bridge and connecting lake wall in the spring of 2014.

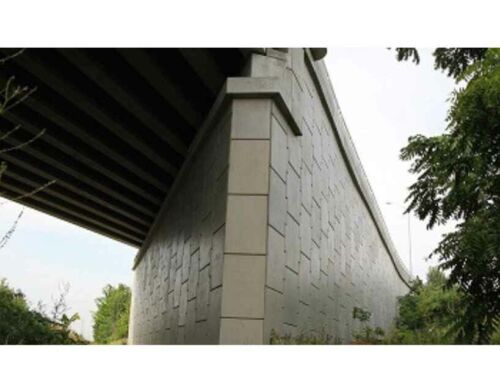

The unique geometry presented challenges for both the designers and installers but in the end resulted in the desired architectural effect. Geometric and architectural enhancements to Reinforced Earth Walls often only add very slightly to the project cost but result in a significant increase in the overall aesthetics of the project.

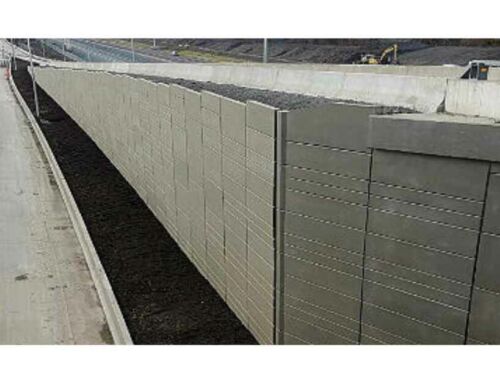

The Reinforced Earth wall is a gravity wall that consists of three (3) major components: precast concrete facing, galvanized steel soil reinforcements and granular backfill. It is proportioned and designed internally to resist the applied loads in accordance with well-established standards. The inherent compressive and shear strength properties of the soil are improved by the tensile strength of the soil reinforcements in these structures. A positive connection design of the reinforcement with the facing of the Reinforced Earth wall is required to prevent overstressing at the connection and to minimize post-construction movement. This wall is designed based on the Canadian Highway Bridge Design Code (CHBDC) CSA S6-06 and City of Calgary Design Guidelines. The walls are designed for a service life for 75 years.

In the Mahogany development project, the 1.5 meter by 1.5 meter square shape precast panel was chosen for architectural reasons. The square panels are aligned with less than 9m radius curves in some sections. The unique shape of the panel joints, similar to the cruciform panels, enables the square panels to make that curve without excessively opening up the joint in convex curves and closing the joints in the concave curves. Panels have 20mm joints all around the panel to create more flexibility. The joints accommodate relatively large differential settlement which is limited to 1%. In most of the sections, the Reinforced Earth wall is partially submerged (up to 2m); therefore the backfill was specified with low amount of fine content so that the water from artificial pond can flow in and out of the reinforced zone without imposing any hydrostatic pressure. Since the construction season is short in Calgary, a backfill was utilized in this project which is less sensitive for placement in the winter. For this reason, the contractor was able to place and compact the backfill in sub-zero temperatures that increased the productivity and helped the construction schedule. Another unique feature in the project is the Reinforced Earth staircase. The 2.20 meter wide staircase with about 35 stairs was designed and built with Reinforced Earth system and provided a pleasant look to the structure.

As originators of MSE Technology, Reinforced Earth continues to lead the industry in reliability that comes from their years of experience. Clients have grown to trust the name and the products associated with Reinforced Earth and increasingly recognize the difference between RECo and their competitors when it comes to avoiding both construction and post construction problems.