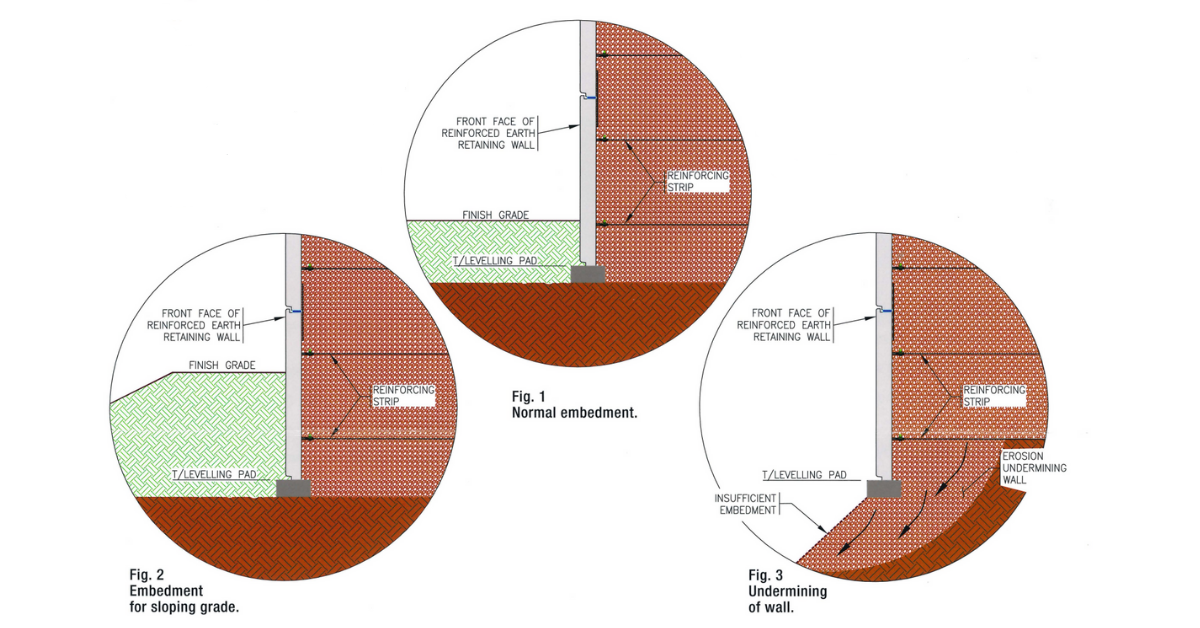

MSE walls are embedded below the finished ground line for a several reasons. The first but least significant reason is for appearance. Since MSE walls use standard panel sizes their base is comprised of a series of steps, which in combination with the leveling pad, produces a less desirable appearance for a finished wall. (See Fig. 1)

The second reason is to provide a local “berm effect”, to improve the resistance of the founda- tion soil against a local punching failure. In this regard some general guidelines are available to determine the embedment depth as a function of the wall height and net surcharge. The relation- ship between wall height and embedment depth is based on very generalized analyzes for a very soft soil type and provides a high degree of assurance against local bearing failure. For most soils the added resistance of the berm is truly not needed.

The other stabilizing effect that the embedment depth has on an MSE wall is it will increase the global stability of the wall compare to a design that had no embedment. The reason for this is by lowering the base of the wall below grade it will automatically lower the soil reinforcement thus driving any potential slip circles deeper into the foundation soil. For this reason geotechnical engineers may specify increased embedment for an MSE wall if the foundation soils are poor. (See Fig. 2)

The final and most important reason for embedding an MSE wall is to provide insurance against the wall ever becoming undermined. Undermining of an MSE wall can be caused either from erosion or local excavations or a combination of both and can result in a situation developing like it shown in Fig. 3 As seen in this figure the undermining of the wall will ultimately result in loss of fill from within the wall which can lead to settlements in the road or land above. For this reason embedment in accordance with the project specifications or the reference code is always strongly recommended. The two single exceptions to this are for 1) walls on sound bedrock where the leveling pad is cast directly on the rock and the second is for 2) temporary walls which can be closely monitored during the construction period, and for which the consequences of undermining are less severe.